There may be a good chance you have heard of Computer Numerical Control (CNC) and laser cutting services before, and are likely to have some sort of idea that they are related to interior design stencils, furniture, and art. But beyond some of the very loose basics, there are recognisable differences between the two cutting services. Thus, if you need to cut a fabricated design out, knowing the distinctions between the two can help you decide on which to choose.

What is CNC cutting?

CNC cutting is a manufacturing process that uses pre-programmed computer software to dictate the movement of factory tools and machinery. CNC machining can be used to control a wide range of complex types of machinery such as grinders, lathes, and milling machines. The use of CNC machining has helped many cutting companies perform three-dimensional cutting tasks and jobs with just a single set of prompts. CNC cutting, unlike traditional cutting, does not require live operators to prompt and guide the commands of machining tools such as levers, buttons, and wheels.

Without manual control limitations, a CNC system might resemble a regular set of components to an onlooker; however, the software programmes and consoles employed are different from regular ones.

In CNC cutting, an expert creates a design based on the customer’s needs using software programmes like AutoCAD. Upon finishing the design, the desired material will be placed on the cutting surface. Computer-Aided Manufacturing (CAM) creates G-codes to be read by the CNC machine and a controller connected will translate the G-codes into electronic signals for the machine to run. From there, the computer determines the shape and cut of the material.

CNC machines typically cut through almost any material, however, some of the more common ones include:

- Metals such as aluminium, brass, or steel

- Wood, while it is not usually chosen, companies offering CNC wood cutting services in Singapore will choose to use hardwood, plywood, or softwood.

- Plastics like acrylics, polypropylene, and polycarbonate

- Foam, though lightweight, is durable, with the two main types being carving foam and rigid foam

The introduction of CNC machines has improved automation, flexibility, consistency whilst producing accurate workpieces.

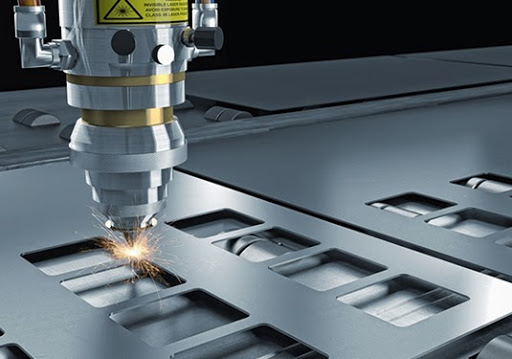

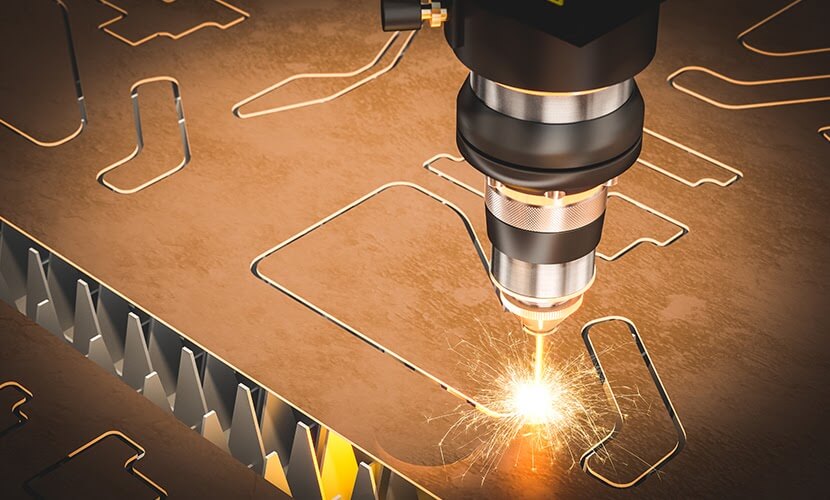

What is laser cutting?

Similar to CNC cutting, laser cut services make use of a CNC system to guide the laser cutting machine. However, the main difference between CNC cutting and laser cut services is the process. Instead of a cutting tool, laser cutting relies on heat energy to create the product’s desired shape. Under CNC control, a continuous cut is produced by moving the laser beam or workpiece. Unlike traditional CNC cutting, there are three major varieties of laser-cut services in Singapore: fusion cutting, flame-cutting, and remote cutting.

Laser cutting is ideally suited for rapid prototyping with an exceptional level of precision and is also an extremely fast method to cut designs using wood or various plastic materials like acrylic.

Differences between CNC and laser cutting

While CNC cutting carves out the design, laser cutting makes use of a high-energy light beam to burn through the material. Even though laser cutting has its limitations and may not work for any material or design, it does offer two main unique advantages over CNC cutting:

- Precision – the fabricator set for laser cutting can be set to cut designs with widths as narrow as under 0.1mm, whereas the tool used for CNC cutting has limited widths. This allows laser cutting to achieve detailed cuts with extreme precision.

- Clean and sealed edges – since laser cutting involves the process of burning, thus the edges are always clean and sealed. Furthermore, the spinning cutter of CNC machines may sometimes tear out the materials around where it is cutting. Hence not only does this improve the functionality of the finished product, it also enhances the appearance.

However, this does not mean that CNC cutting services in Singapore are less preferred than laser cut services. There is often no discolouration of the edges or surfaces on the finished product cut using CNC methods since the material is removed by a spinning cutter head as compared to burning away the edges with a laser beam. CNC cutting also gives greater control over the depth of cut, making it easier to make three-dimensional objects or cuts.

In conclusion, both CNC cutting and laser cutting are efficient and versatile methods used in fabricating precision parts, manufacturing components, and intricate designs. Hence, it is ideal that you pick a cutting service that meets your needs.

At Cutting Edge, we have the experience and expertise to help you with any CNC or laser cutting needs. Let us help you put your designs a cut above the rest, reach out to us today to find out more.